Leading Smls Pipe and fittings supplier from China since 1991

Carbon Seamless Steel Pipe: Unrivaled Strength and Versatility for Industrial Excellence

The most defining feature of a carbon seamless steel pipe lies in its seamless construction.

Jul 17,2025

In the complex web of industrial infrastructure, the carbon seamless steel pipe emerges as a true unsung hero. Its unique manufacturing process and exceptional properties make it an indispensable component across a multitude of sectors, setting it apart from other piping solutions.

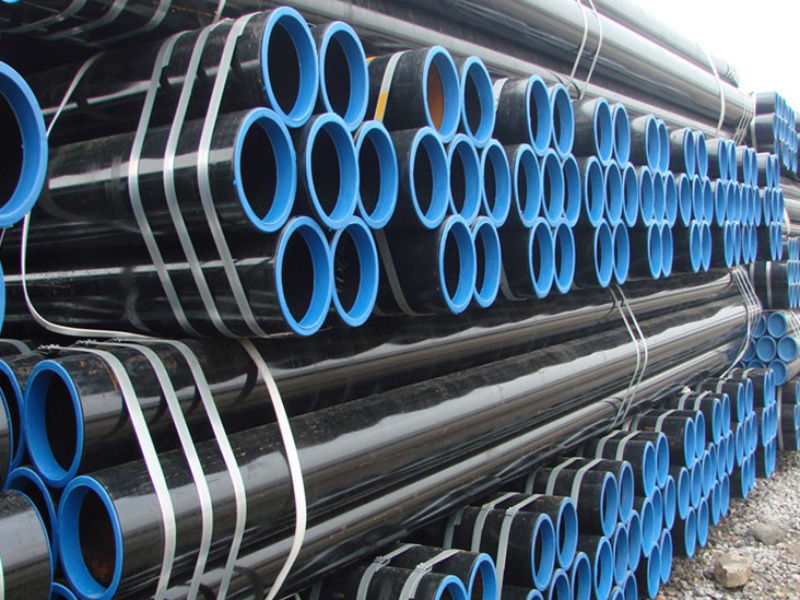

The Power of Seamlessness

The most defining feature of a carbon seamless steel pipe lies in its seamless construction. Unlike welded pipes, which have a joint that can be a potential weak point, these pipes are manufactured through a process that involves piercing a solid billet and then rolling it into a hollow tube without any welding. This results in a pipe with a uniform structure throughout, eliminating the risk of leakage at welded seams. This is especially critical in applications where the transportation of hazardous or high-pressure fluids is involved, such as in the oil and gas industry. Even under extreme pressure, the carbon seamless steel pipe maintains its integrity, ensuring safe and reliable operation.

Exceptional Mechanical Properties

High Tensile Strength

Carbon seamless steel pipes boast impressive tensile strength, making them capable of withstanding heavy loads and high-pressure environments. This strength is derived from the quality carbon steel used in their production, which undergoes precise heat treatment to enhance its mechanical properties. In industrial settings where pipes are subjected to intense pressure, such as in hydraulic systems or high-pressure steam lines, the high tensile strength of these pipes ensures that they do not deform or burst, providing long-term durability.

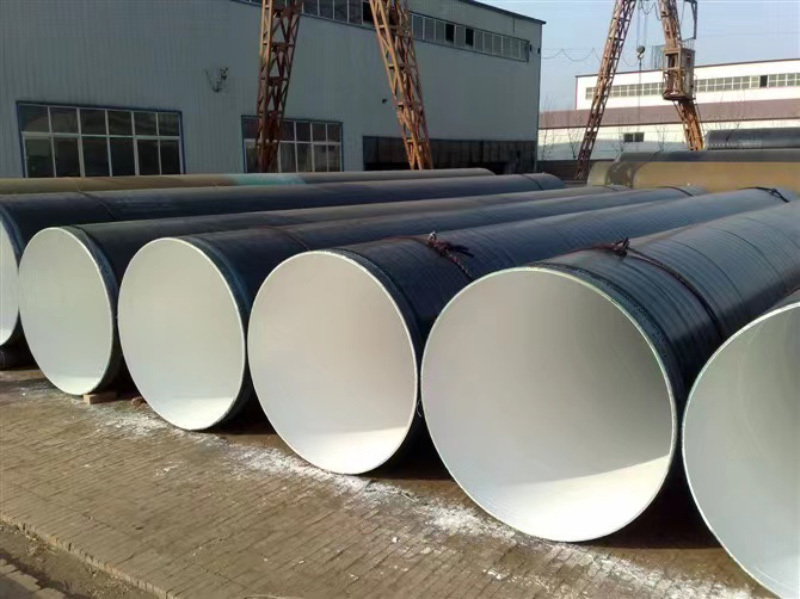

Excellent Corrosion Resistance

While carbon steel is not as corrosion-resistant as some stainless steel alloys, carbon seamless steel pipes can be treated with various coatings or galvanization to significantly improve their resistance to corrosion. This treatment allows them to perform well in environments where they may come into contact with moisture, chemicals, or other corrosive substances. For example, in water treatment plants or chemical processing facilities, where pipes are constantly exposed to corrosive elements, properly treated carbon seamless steel pipes can have a long service life, reducing maintenance costs and downtime.

Superior Ductility

Ductility is another key property of carbon seamless steel pipes. They can be easily bent, shaped, and formed without cracking, which gives them great flexibility in installation. This is particularly useful in projects where pipes need to navigate around obstacles or fit into tight spaces. Whether it's in a complex industrial layout or a building's plumbing system, the ductility of these pipes makes the installation process more efficient and adaptable.

Wide Range of Applications

Oil and Gas Industry

The oil and gas industry is one of the largest users of carbon seamless steel pipes. They are used for drilling, transporting crude oil and natural gas from the wellhead to refineries, and distributing finished products. The pipes' ability to handle high pressure and harsh conditions makes them ideal for this industry. From deep-sea drilling rigs to long-distance pipelines, carbon seamless steel pipes ensure the safe and efficient transportation of oil and gas resources.

Construction Sector

In the construction sector, carbon seamless steel pipes are used in a variety of applications, including structural support, plumbing, and HVAC systems. They are used as columns, beams, and trusses in building structures, providing strong and stable support. In plumbing systems, they are used to transport water, sewage, and other fluids. Their durability and reliability make them a preferred choice for construction projects of all sizes, from residential buildings to large commercial complexes.

Automotive Industry

The automotive industry also relies on carbon seamless steel pipes for various components. They are used in exhaust systems, fuel lines, and hydraulic systems. The high strength and heat resistance of these pipes make them suitable for the high-temperature and high-pressure environments within a vehicle's engine and exhaust system. Their lightweight nature also helps in improving fuel efficiency, which is a key consideration in modern automotive design.

Power Generation

Power generation facilities, such as thermal power plants and nuclear power plants, use carbon seamless steel pipes in boilers, turbines, and cooling systems. The pipes are able to withstand the high temperatures and pressures generated in these systems, ensuring the efficient operation of power generation equipment. They play a crucial role in the transfer of heat and fluids, contributing to the reliable production of electricity.