Leading Smls Pipe and fittings supplier from China since 1991

Exploring the Latest Innovations in OCTG Casing and Tubing

Another trend in the realm of OCTG casing and tubing is the integration of advanced technology such as digital monitoring systems.

Apr 18,2025

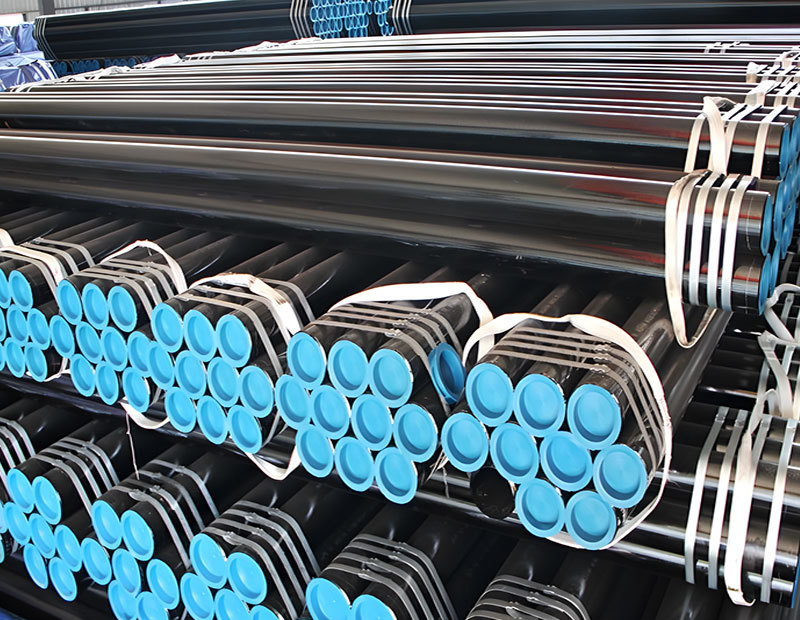

In the oil and gas industry, OCTG (Oil Country Tubular Goods) casing and tubing play a vital role in ensuring the safe and efficient extraction of hydrocarbons. As the industry continues to evolve, the demand for the newest OCTG casing and tubing is more pronounced than ever. Let’s explore the latest innovations and trends that are shaping these critical components.

One of the most significant advancements in OCTG casing and tubing is the development of high-strength materials. Modern materials are often engineered to withstand extreme conditions, including high pressure, temperature fluctuations, and corrosive environments. This enhanced durability not only extends the lifespan of the casing and tubing but also reduces the likelihood of failures during operations, thereby improving overall safety and efficiency.

Additionally, advancements in manufacturing processes have led to the production of OCTG casing and tubing with superior dimensional accuracy and surface finishes. These improvements are pivotal in ensuring a better fit during installation, which can significantly minimize risks associated with leaks and failures. The precision-engineered components are designed to meet the rigorous standards set by the industry, ensuring compatibility with various drilling techniques and environments.

Another trend in the realm of OCTG casing and tubing is the integration of advanced technology such as digital monitoring systems. These systems enable operators to monitor the performance of the casing and tubing in real-time, allowing for proactive maintenance and immediate response to any anomalies. Such technology not only enhances operational efficiency but also contributes to safer drilling practices by detecting potential issues before they escalate.

Moreover, the focus on sustainability has prompted manufacturers to explore eco-friendly options in the production of OCTG casing and tubing. This includes the use of recycled materials and processes that minimize environmental impact. As the industry shifts towards more sustainable practices, the demand for these innovative products is expected to grow, reflecting a broader commitment to environmental stewardship.

Lastly, the newest OCTG casing and tubing are being designed with adaptability in mind. With the rise of unconventional oil and gas extraction methods, such as fracking and horizontal drilling, the industry requires components that can perform under varying conditions. The latest designs often incorporate features that enhance flexibility and adaptability, ensuring that they can meet the diverse needs of today’s drilling operations.

In conclusion, the newest OCTG casing and tubing represent a fusion of advanced materials, innovative manufacturing processes, and cutting-edge technology. These developments not only enhance the performance and reliability of these crucial components but also align with the industry's evolving demands for safety and sustainability. As the oil and gas sector continues to advance, staying abreast of these innovations will be essential for professionals seeking to optimize their operations.

Hot Tags: