Leading Smls Pipe and fittings supplier from China since 1991

Understanding ASTM Seamless Pipe: A Comprehensive Guide for Professionals

When it comes to structural integrity and durability in construction, the choice of materials is paramount. One such material that has gained prominence in the industry is the ASTM seamless pipe. The acronym ASTM stands for the American Society for Testing and Materials, which develops and publishes technical standards for a wide range of materials, including pipes. ASTM seamless pipes are manufac

Feb 07,2025

When it comes to structural integrity and durability in construction, the choice of materials is paramount. One such material that has gained prominence in the industry is the ASTM seamless pipe. The acronym ASTM stands for the American Society for Testing and Materials, which develops and publishes technical standards for a wide range of materials, including pipes.

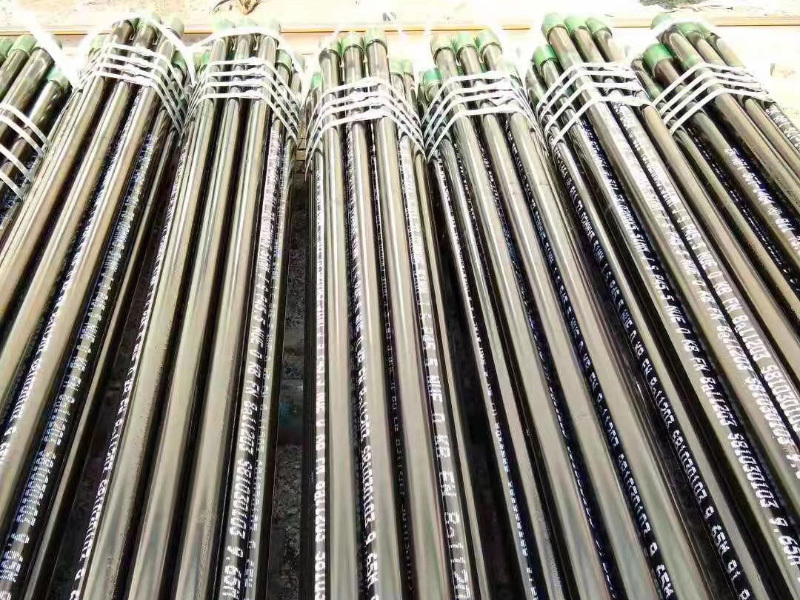

ASTM seamless pipes are manufactured without any joints or welds, resulting in a product known for its strength and reliability. This seamless construction makes them less prone to leakage and provides better resistance to pressure and temperature fluctuations compared to welded pipes. The absence of seams also ensures uniformity in the wall thickness, which is critical in maintaining structural integrity under various load conditions.

The production of ASTM seamless pipes involves a variety of manufacturing processes, including hot finishing and cold finishing methods. These processes help in achieving the desired mechanical properties and surface finish. Seamless pipes are available in different grades, which define their chemical composition and mechanical characteristics. Professionals in the construction industry often refer to these grades to ensure that the pipes meet specific project requirements.

One of the key benefits of using ASTM seamless pipes is their versatility. They can be utilized in numerous applications, ranging from oil and gas pipelines to structural components in buildings. The durability of these pipes makes them suitable for both high-pressure and high-temperature environments, which is a common requirement in industrial applications.

Additionally, seamless pipes comply with rigorous industry standards, ensuring that they meet safety and performance benchmarks. This compliance also simplifies the process of obtaining necessary permits and approvals for construction projects, further streamlining project timelines.

Furthermore, when considering sustainability, ASTM seamless pipes are often favored due to their longer lifespan and reduced need for replacement compared to other types of pipes. Their resistance to corrosion, especially when treated with appropriate coatings, also contributes to a lower environmental impact over time.

In conclusion, ASTM seamless pipes represent a critical component in the architecture and construction sectors. Their unique manufacturing process, combined with their mechanical advantages and compliance with industry standards, make them an indispensable choice for professionals looking to ensure durability and performance in their projects. Understanding the specifications and applications of ASTM seamless pipes can enhance decision-making and lead to more successful project outcomes.

ASTM seamless pipes are manufactured without any joints or welds, resulting in a product known for its strength and reliability. This seamless construction makes them less prone to leakage and provides better resistance to pressure and temperature fluctuations compared to welded pipes. The absence of seams also ensures uniformity in the wall thickness, which is critical in maintaining structural integrity under various load conditions.

The production of ASTM seamless pipes involves a variety of manufacturing processes, including hot finishing and cold finishing methods. These processes help in achieving the desired mechanical properties and surface finish. Seamless pipes are available in different grades, which define their chemical composition and mechanical characteristics. Professionals in the construction industry often refer to these grades to ensure that the pipes meet specific project requirements.

One of the key benefits of using ASTM seamless pipes is their versatility. They can be utilized in numerous applications, ranging from oil and gas pipelines to structural components in buildings. The durability of these pipes makes them suitable for both high-pressure and high-temperature environments, which is a common requirement in industrial applications.

Additionally, seamless pipes comply with rigorous industry standards, ensuring that they meet safety and performance benchmarks. This compliance also simplifies the process of obtaining necessary permits and approvals for construction projects, further streamlining project timelines.

Furthermore, when considering sustainability, ASTM seamless pipes are often favored due to their longer lifespan and reduced need for replacement compared to other types of pipes. Their resistance to corrosion, especially when treated with appropriate coatings, also contributes to a lower environmental impact over time.

In conclusion, ASTM seamless pipes represent a critical component in the architecture and construction sectors. Their unique manufacturing process, combined with their mechanical advantages and compliance with industry standards, make them an indispensable choice for professionals looking to ensure durability and performance in their projects. Understanding the specifications and applications of ASTM seamless pipes can enhance decision-making and lead to more successful project outcomes.

Hot Tags: