Leading Smls Pipe and fittings supplier from China since 1991

Understanding OCTG Casing and Tubing: Essential Components in the Oil and Gas Industry

In the oil and gas industry, OCTG (Oil Country Tubular Goods) casing and tubing are vital components that ensure the safe and efficient extraction of hydrocarbons from subterranean reservoirs. Understanding these elements can provide insight into their importance within drilling operations and well integrity. **What are OCTG Casing and Tubing?** OCTG is a collective term that encompasses various t

Feb 15,2025

In the oil and gas industry, OCTG (Oil Country Tubular Goods) casing and tubing are vital components that ensure the safe and efficient extraction of hydrocarbons from subterranean reservoirs. Understanding these elements can provide insight into their importance within drilling operations and well integrity.

**What are OCTG Casing and Tubing?**

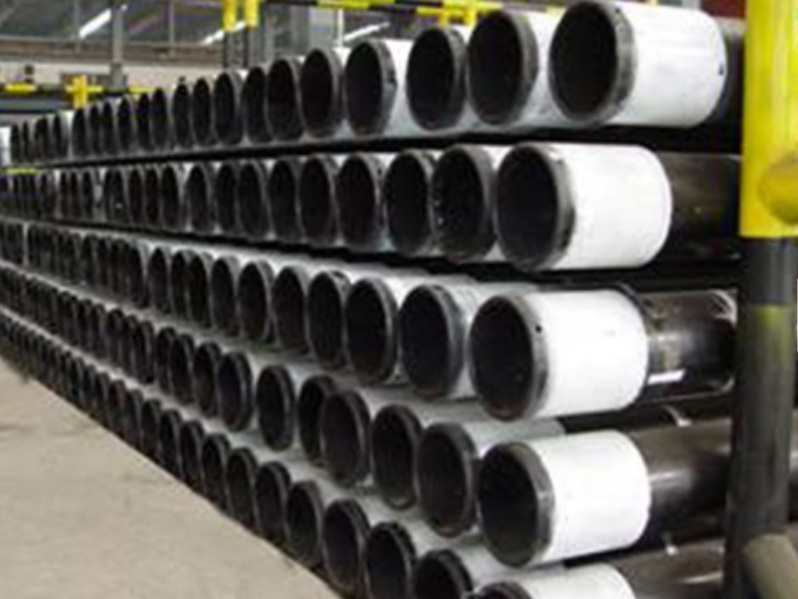

OCTG is a collective term that encompasses various tubular products utilized in oil and gas operations. Casing refers to the large-diameter pipes that are installed in the wellbore to stabilize the well and prevent any collapse during and after drilling. It forms the outer layer of the well structure and provides a protective barrier against contamination, thereby safeguarding both the environment and the extracted resources.

On the other hand, tubing refers to the smaller-diameter pipes that are inserted inside the casing. Tubing serves as the conduit through which oil and gas are brought to the surface after extraction. It is designed to withstand high pressures and harsh conditions, ensuring that the flow of hydrocarbons remains uninterrupted.

**Types of Casing and Tubing**

There are various types of OCTG casing and tubing available, each designed for specific applications and environments. The most common types of casing include surface casing, intermediate casing, and production casing, each serving unique purposes during different stages of the drilling process. Similarly, tubing can vary in size and thickness depending on the pressure and type of fluids it will manage.

Material selection is also crucial when it comes to OCTG products. Common materials include carbon steel and alloy steel, which offer the required strength and durability to withstand the demanding conditions in which they operate. Corrosion-resistant alloys may also be employed in specific environments to enhance longevity and performance.

**Importance of Quality and Standards**

The integrity of OCTG casing and tubing is paramount to the success of any drilling operation. Quality standards and regulatory compliance play a significant role in ensuring that these products can withstand the pressures and challenges they encounter. Manufacturers and operators must adhere to industry standards set by organizations such as the American Petroleum Institute (API) to ensure safety and reliability.

**Conclusion**

In summary, OCTG casing and tubing are integral components of oil and gas extraction processes. Their proper selection, installation, and maintenance directly influence the efficiency and safety of drilling operations. Understanding the functionalities and characteristics of these products not only enhances operational effectiveness but also contributes to the sustainability and environmental protection within the energy sector. Investing in quality OCTG casing and tubing ensures that companies can achieve optimal performance while minimizing risks associated with well integrity and environmental impact.

**What are OCTG Casing and Tubing?**

OCTG is a collective term that encompasses various tubular products utilized in oil and gas operations. Casing refers to the large-diameter pipes that are installed in the wellbore to stabilize the well and prevent any collapse during and after drilling. It forms the outer layer of the well structure and provides a protective barrier against contamination, thereby safeguarding both the environment and the extracted resources.

On the other hand, tubing refers to the smaller-diameter pipes that are inserted inside the casing. Tubing serves as the conduit through which oil and gas are brought to the surface after extraction. It is designed to withstand high pressures and harsh conditions, ensuring that the flow of hydrocarbons remains uninterrupted.

**Types of Casing and Tubing**

There are various types of OCTG casing and tubing available, each designed for specific applications and environments. The most common types of casing include surface casing, intermediate casing, and production casing, each serving unique purposes during different stages of the drilling process. Similarly, tubing can vary in size and thickness depending on the pressure and type of fluids it will manage.

Material selection is also crucial when it comes to OCTG products. Common materials include carbon steel and alloy steel, which offer the required strength and durability to withstand the demanding conditions in which they operate. Corrosion-resistant alloys may also be employed in specific environments to enhance longevity and performance.

**Importance of Quality and Standards**

The integrity of OCTG casing and tubing is paramount to the success of any drilling operation. Quality standards and regulatory compliance play a significant role in ensuring that these products can withstand the pressures and challenges they encounter. Manufacturers and operators must adhere to industry standards set by organizations such as the American Petroleum Institute (API) to ensure safety and reliability.

**Conclusion**

In summary, OCTG casing and tubing are integral components of oil and gas extraction processes. Their proper selection, installation, and maintenance directly influence the efficiency and safety of drilling operations. Understanding the functionalities and characteristics of these products not only enhances operational effectiveness but also contributes to the sustainability and environmental protection within the energy sector. Investing in quality OCTG casing and tubing ensures that companies can achieve optimal performance while minimizing risks associated with well integrity and environmental impact.

Hot Tags: