Leading Smls Pipe and fittings supplier from China since 1991

Unlocking Efficiency: The Role of API Line Pipes in Automotive Applications

Unlocking Efficiency: The Role of API Line Pipes in Automotive Applications Table of Contents 1. Introduction to API Line Pipes in Automotive Applications 2. Understanding API Line Pipes 3. Significance of API Line Pipes in the Automotive Industry 4. Benefits of Using API Line Pipes in Automotive Applications 5. Materials and Manufacturing Process of API Line Pipes 6. Appl

Jul 17,2025

Unlocking Efficiency: The Role of API Line Pipes in Automotive Applications

Table of Contents

- 1. Introduction to API Line Pipes in Automotive Applications

- 2. Understanding API Line Pipes

- 3. Significance of API Line Pipes in the Automotive Industry

- 4. Benefits of Using API Line Pipes in Automotive Applications

- 5. Materials and Manufacturing Process of API Line Pipes

- 6. Applications of API Line Pipes in Automotive Systems

- 7. Innovations and Advancements in API Line Pipes

- 8. Maintenance and Safety Considerations for API Line Pipes

- 9. Frequently Asked Questions (FAQ)

- 10. Conclusion

1. Introduction to API Line Pipes in Automotive Applications

In the realm of modern automotive engineering, efficiency is not merely a goal; it is a necessity. As vehicles become increasingly complex and demands for performance soar, the components that facilitate these advancements must also evolve. One such component that plays a pivotal role in enhancing automotive efficiency is the **API line pipe**. These pipes are integral to various automotive systems, contributing to overall vehicle performance, safety, and sustainability.

2. Understanding API Line Pipes

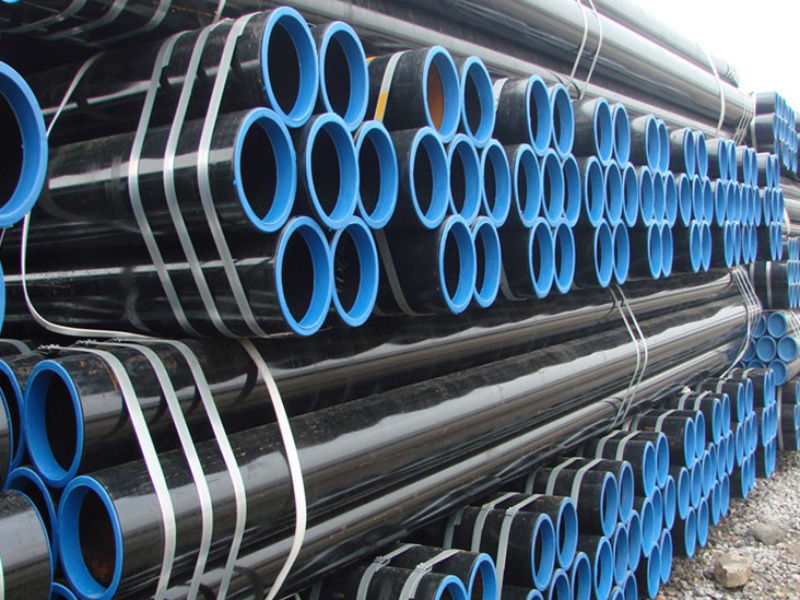

API line pipes, which stand for **American Petroleum Institute** line pipes, are manufactured to meet stringent standards required for the transport of fluids and gases in various applications, including automotive. They are specifically designed to withstand high pressures and temperatures, making them ideal for automotive systems that require reliable fluid transport, such as oil, fuel, and coolant lines.

The design of API line pipes includes various specifications regarding material strength, ductility, and resistance to corrosion, ensuring that these pipes can effectively operate in the challenging environments typical of automotive applications.

3. Significance of API Line Pipes in the Automotive Industry

The automotive industry continually seeks innovations that promote **efficiency, safety, and cost-effectiveness**. API line pipes are significant for several reasons:

1. **Fluid Management**: API line pipes ensure the efficient management of fluids necessary for vehicle operation. They are utilized to transport engine oil, fuel, and coolant, which are essential for engine performance and longevity.

2. **Safety Enhancements**: The integrity of API line pipes is crucial for safety. Leaks or failures can lead to accidents and costly repairs. High-quality API line pipes provide reliability under various operating conditions to minimize these risks.

3. **Environmental Impact**: With increasing regulatory pressures, the automotive industry must also address environmental concerns. API line pipes contribute to reduced emissions and improved fuel efficiency, aligning with sustainability goals.

4. Benefits of Using API Line Pipes in Automotive Applications

The adoption of API line pipes in automotive systems presents several compelling benefits:

### h3>4.1 Enhanced Durability

API line pipes are constructed from high-grade materials that impart exceptional durability. This durability translates to longer lifespans for automotive systems, reducing the frequency of replacements and associated costs.

### h3>4.2 Improved Efficiency

These pipes facilitate smooth fluid flow, minimizing resistance and enhancing the overall efficiency of the vehicle’s engine. An efficient engine consumes less fuel and emits fewer pollutants, a crucial aspect of modern automotive design.

### h3>4.3 Versatile Applications

API line pipes are versatile and can be tailored for various automotive applications, including:

- Fuel lines

- Oil cooler lines

- Brake lines

- Power steering lines

This versatility makes them a preferred choice among automotive manufacturers.

### h3>4.4 Cost-Effectiveness

While API line pipes may represent a higher initial investment compared to lower-quality alternatives, their durability and efficiency lead to long-term cost savings. Reduced maintenance and fewer replacements contribute to a lower total cost of ownership.

5. Materials and Manufacturing Process of API Line Pipes

The quality of API line pipes is directly tied to the materials used in their construction and the manufacturing processes employed.

### h3>5.1 Common Materials

API line pipes are typically made from carbon steel, stainless steel, or alloy steel, known for their strength and resistance to corrosion. The choice of material depends on the specific application and operating conditions.

### h3>5.2 Manufacturing Processes

The manufacturing of API line pipes involves several stages, including:

1. **Raw Material Selection**: High-quality raw materials are selected to ensure durability.

2. **Forming**: Pipes are formed using processes such as extrusion or rolling.

3. **Heat Treatment**: Heat treatment enhances the mechanical properties of the pipes, providing strength and ductility.

4. **Testing and Inspection**: Each pipe undergoes rigorous testing to ensure compliance with API standards, including pressure testing, dimensional inspections, and surface quality assessments.

6. Applications of API Line Pipes in Automotive Systems

API line pipes serve critical functions in various automotive systems. Their applications include:

### h3>6.1 Fuel Systems

In fuel systems, API line pipes maintain the transportation of fuel from the tank to the engine, ensuring optimal delivery under varying conditions. Their ability to handle high pressures makes them essential for modern fuel injection systems.

### h3>6.2 Engine Cooling

API line pipes play a vital role in engine cooling systems by transporting coolant between the engine and radiator. This circulation is crucial for maintaining optimal engine temperatures and preventing overheating.

### h3>6.3 Lubrication Systems

In lubrication systems, these pipes transport oil to various engine components, reducing friction and wear. Proper lubrication is essential for engine longevity and performance.

### h3>6.4 Hydraulic Systems

API line pipes are also used in hydraulic systems, such as power steering and braking systems, where fluid pressure is crucial for operation. Their reliability ensures that these systems function safely and effectively.

7. Innovations and Advancements in API Line Pipes

The automotive industry is characterized by continuous innovation, and API line pipes are no exception. Recent advancements include:

### h3>7.1 Lightweight Materials

The development of lightweight materials has led to the creation of API line pipes that reduce overall vehicle weight, enhancing fuel efficiency without compromising strength.

### h3>7.2 Enhanced Corrosion Resistance

Innovations in coatings and treatments have improved the corrosion resistance of API line pipes, extending their lifespan and reliability in harsh environments.

### h3>7.3 Smart Technology Integration

The integration of smart technologies, such as sensors within API line pipes, allows for real-time monitoring of fluid flow and pressure, providing valuable data for predictive maintenance and enhancing safety.

8. Maintenance and Safety Considerations for API Line Pipes

While API line pipes are designed for durability, proper maintenance is essential to ensure their longevity and performance.

### h3>8.1 Regular Inspections

Routine inspections of API line pipes for signs of wear or damage can prevent catastrophic failures. Look for leaks, corrosion, or physical damage during maintenance checks.

### h3>8.2 Proper Installation

Ensuring that API line pipes are installed correctly is crucial. Misalignment or incorrect fittings can lead to leaks or pressure loss, compromising system integrity.

### h3>8.3 Adherence to Standards

Adhering to industry standards and regulations during the selection and installation of API line pipes is vital for safety. Compliance with API specifications ensures that the pipes can withstand the demands of automotive applications.

9. Frequently Asked Questions (FAQ)

### h3>9.1 What are API line pipes used for in automotive applications?

API line pipes are primarily used for transporting fluids such as fuel, oil, and coolant within various automotive systems.

### h3>9.2 How do API line pipes enhance vehicle efficiency?

They enhance efficiency by ensuring smooth and reliable fluid flow, reducing resistance, and improving overall engine performance.

### h3>9.3 What materials are typically used in API line pipes?

API line pipes are commonly made from carbon steel, stainless steel, or alloy steel, chosen for their strength and corrosion resistance.

### h3>9.4 How can I ensure the longevity of API line pipes?

Regular inspections, proper installation, and adherence to industry standards are crucial to maintaining the longevity of API line pipes.

### h3>9.5 What innovations are currently shaping API line pipe technology?

Innovations include the use of lightweight materials, enhanced corrosion resistance, and the integration of smart technologies for monitoring.

10. Conclusion

API line pipes are indispensable components in the automotive industry, contributing significantly to efficiency, safety, and performance. Their robust design and versatile applications make them a preferred choice for manufacturers seeking to enhance vehicle functionalities. As innovations continue to emerge, the role of API line pipes will only grow, further unlocking the potential of automotive applications. Investing in high-quality API line pipes is a strategic move for anyone looking to ensure reliability and efficiency in their automotive systems.

Hot Tags: