Leading Smls Pipe and fittings supplier from China since 1991

Understanding Seamless Steel Pipe API 5L X60: A Key Resource in Construction

In the realm of construction and decorative materials, seamless steel pipes play a crucial role, particularly those conforming to API 5L X60 specifications. API 5L covers a specification for line pipe, which is extensively used in the transportation of oil and natural gas. The X60 grade represents a specific yield strength of 60,000 psi, making it a robust choice for demanding applications. One of

Oct 21,2025

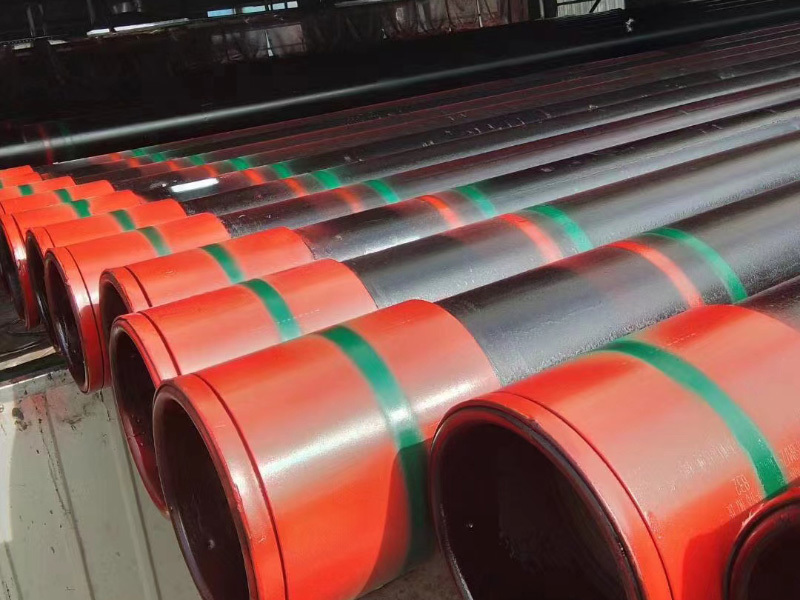

In the realm of construction and decorative materials, seamless steel pipes play a crucial role, particularly those conforming to API 5L X60 specifications. API 5L covers a specification for line pipe, which is extensively used in the transportation of oil and natural gas. The X60 grade represents a specific yield strength of 60,000 psi, making it a robust choice for demanding applications.

One of the primary advantages of seamless steel pipes, especially those adhering to the API 5L X60 standard, is their structural integrity. Unlike welded pipes, seamless pipes are manufactured from a single piece of steel, resulting in a uniform wall thickness and eliminating the risk of weld-related weaknesses. This characteristic is especially important in high-pressure environments often encountered in construction and infrastructure projects.

Seamless steel pipes are renowned for their durability and resilience against various environmental factors. They exhibit excellent corrosion resistance, particularly when coated or treated appropriately, making them suited for both underground and above-ground installations. This durability extends the lifespan of the structures they support, reducing maintenance costs over time.

In construction, seamless steel pipes API 5L X60 are commonly used for structural supports, water supply lines, and gas distribution systems. Their high tensile strength and flexibility allow engineers to design more efficient and reliable systems, essential for both residential and commercial projects. Moreover, their ability to withstand extreme temperatures and pressures also makes them a preferred material in industrial applications.

Another noteworthy aspect of seamless steel pipes is their versatility. They can be manufactured in various diameters and wall thicknesses, catering to specific project requirements. This customization allows construction professionals to choose the right type of pipe for their unique needs, ensuring optimal performance and safety.

The manufacturing process of seamless steel pipes involves advanced techniques like extrusion or rotary piercing, which further enhances their quality and performance characteristics. These methods guarantee a high level of precision and consistency in production, which is essential for meeting the stringent standards required in the construction industry.

In summary, seamless steel pipes API 5L X60 are a vital component in modern construction practices, offering unparalleled strength, reliability, and adaptability. Their unique properties make them suitable for a wide range of applications, contributing to the safety and efficiency of construction projects worldwide. As the industry continues to evolve, the demand for such high-quality materials will undoubtedly remain strong, emphasizing the importance of understanding their benefits and applications.

One of the primary advantages of seamless steel pipes, especially those adhering to the API 5L X60 standard, is their structural integrity. Unlike welded pipes, seamless pipes are manufactured from a single piece of steel, resulting in a uniform wall thickness and eliminating the risk of weld-related weaknesses. This characteristic is especially important in high-pressure environments often encountered in construction and infrastructure projects.

Seamless steel pipes are renowned for their durability and resilience against various environmental factors. They exhibit excellent corrosion resistance, particularly when coated or treated appropriately, making them suited for both underground and above-ground installations. This durability extends the lifespan of the structures they support, reducing maintenance costs over time.

In construction, seamless steel pipes API 5L X60 are commonly used for structural supports, water supply lines, and gas distribution systems. Their high tensile strength and flexibility allow engineers to design more efficient and reliable systems, essential for both residential and commercial projects. Moreover, their ability to withstand extreme temperatures and pressures also makes them a preferred material in industrial applications.

Another noteworthy aspect of seamless steel pipes is their versatility. They can be manufactured in various diameters and wall thicknesses, catering to specific project requirements. This customization allows construction professionals to choose the right type of pipe for their unique needs, ensuring optimal performance and safety.

The manufacturing process of seamless steel pipes involves advanced techniques like extrusion or rotary piercing, which further enhances their quality and performance characteristics. These methods guarantee a high level of precision and consistency in production, which is essential for meeting the stringent standards required in the construction industry.

In summary, seamless steel pipes API 5L X60 are a vital component in modern construction practices, offering unparalleled strength, reliability, and adaptability. Their unique properties make them suitable for a wide range of applications, contributing to the safety and efficiency of construction projects worldwide. As the industry continues to evolve, the demand for such high-quality materials will undoubtedly remain strong, emphasizing the importance of understanding their benefits and applications.

Hot Tags: