Leading Smls Pipe and fittings supplier from China since 1991

Why Carbon Steel Seamless Tubes Are Essential for Durable Structural Support

Why Carbon Steel Seamless Tubes Are Essential for Durable Structural Support Table of Contents 1. Introduction to Carbon Steel Seamless Tubes 2. Understanding Structural Support in Construction 3. The Advantages of Carbon Steel Seamless Tubes 3.1 Exceptional Strength and Durability 3.2 Corrosion Resistance 3.3 Cost-Effectiveness 3.4 Lightweight Design 4. Applications of Carbon St

Nov 04,2025

Why Carbon Steel Seamless Tubes Are Essential for Durable Structural Support

Table of Contents

1. Introduction to Carbon Steel Seamless Tubes

2. Understanding Structural Support in Construction

3. The Advantages of Carbon Steel Seamless Tubes

3.1 Exceptional Strength and Durability

3.2 Corrosion Resistance

3.3 Cost-Effectiveness

3.4 Lightweight Design

4. Applications of Carbon Steel Seamless Tubes in Structural Support

4.1 Use in Construction Projects

4.2 Role in Oil and Gas Industries

4.3 Applications in Transportation Infrastructure

5. Manufacturing Process of Carbon Steel Seamless Tubes

6. Quality Standards and Certifications

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction to Carbon Steel Seamless Tubes

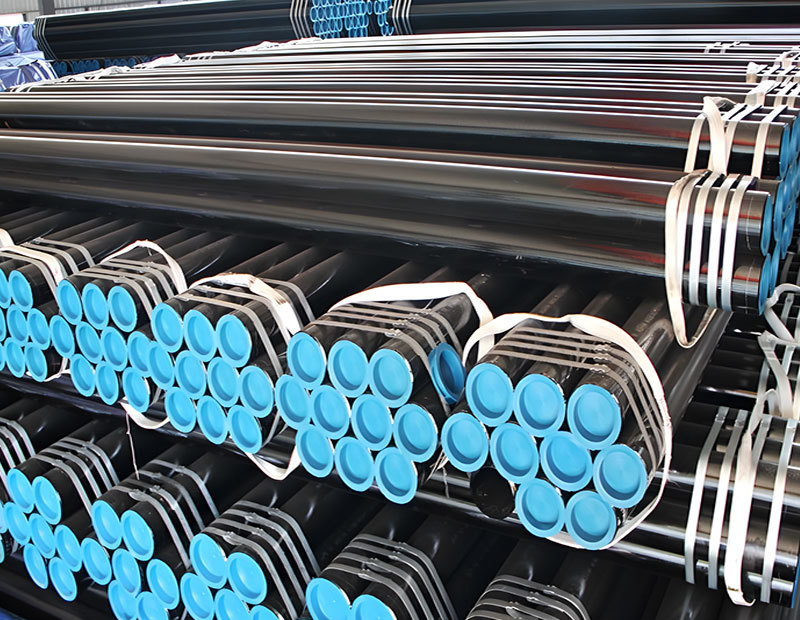

Carbon steel seamless tubes are integral components in the construction and engineering sectors. These tubes are formed from solid round steel billets and do not require welds or joints, making them ideal for various structural applications. Their ability to withstand high pressure and extreme temperatures makes them a top choice among engineers and architects.

2. Understanding Structural Support in Construction

Structural support is a critical aspect of building design, ensuring stability and safety. It refers to the various elements that provide load-bearing capabilities to a structure, preventing collapse or deformation. When selecting materials for structural support, it is essential to consider strength, durability, and resistance to environmental factors.

3. The Advantages of Carbon Steel Seamless Tubes

Choosing carbon steel seamless tubes offers numerous advantages, making them the preferred option in many structural applications.

3.1 Exceptional Strength and Durability

Carbon steel is known for its high strength-to-weight ratio, allowing for the construction of robust frameworks. Seamless tubes maintain uniform wall thickness, which enhances their ability to withstand mechanical stresses and extreme conditions. This durability ensures that structures remain intact over extended periods, reducing the need for frequent repairs.

3.2 Corrosion Resistance

While carbon steel is susceptible to corrosion, seamless tubes can be treated with protective coatings that enhance their resistance to environmental factors. This treatment extends the lifespan of the tubes and reduces maintenance costs, making them an economically viable choice.

3.3 Cost-Effectiveness

The manufacturing process of seamless tubes eliminates the need for joints, which can be points of weakness. This efficiency translates into cost savings during both production and installation. Additionally, their durability reduces the costs associated with repairs and replacements over time.

3.4 Lightweight Design

Compared to other materials, carbon steel seamless tubes are relatively lightweight, making them easier to transport and install. This characteristic is particularly beneficial in projects where weight restrictions are crucial, such as in high-rise buildings or bridges.

4. Applications of Carbon Steel Seamless Tubes in Structural Support

Carbon steel seamless tubes find applications in various industries, contributing significantly to structural integrity.

4.1 Use in Construction Projects

In the construction industry, seamless tubes are commonly used in the framework of buildings, providing essential support for roofs, walls, and floors. Their strength allows architects to design larger open spaces without the need for excessive supports.

4.2 Role in Oil and Gas Industries

The oil and gas sector relies heavily on carbon steel seamless tubes for pipelines and structural supports. These tubes are capable of withstanding high pressures and harsh environmental conditions, essential for safe and efficient transport of resources.

4.3 Applications in Transportation Infrastructure

Carbon steel seamless tubes are integral to transportation infrastructure, including bridges, railways, and highways. Their durability and strength ensure that these structures can withstand heavy loads and adverse weather conditions.

5. Manufacturing Process of Carbon Steel Seamless Tubes

The manufacturing process of carbon steel seamless tubes involves several key stages, including heating, piercing, and elongation. Initially, steel billets are heated to a high temperature, then pierced to create a hollow tube. This tube is then elongated to the desired length through a series of controlled processes, ensuring uniform thickness and quality.

6. Quality Standards and Certifications

To guarantee the reliability of carbon steel seamless tubes, various quality standards and certifications are in place. These include ASTM, ISO, and ASME certifications, which ensure that products meet specific safety and performance criteria. Compliance with these standards is crucial for maintaining structural integrity in construction projects.

7. Frequently Asked Questions (FAQs)

What is the primary advantage of seamless tubes over welded tubes?

Seamless tubes offer improved strength and reliability as they do not have joints that can be potential weak points, unlike welded tubes.

How do carbon steel seamless tubes resist corrosion?

Seamless tubes can be treated with protective coatings, such as galvanization, to enhance their corrosion resistance.

What industries commonly use carbon steel seamless tubes?

Common applications include construction, oil and gas, transportation, and manufacturing.

Can carbon steel seamless tubes be recycled?

Yes, carbon steel is highly recyclable, making it an environmentally friendly choice for construction materials.

How do I choose the right size of seamless tube for my project?

Selecting the right size depends on project specifications, load requirements, and environmental conditions. Consulting with a structural engineer can provide guidance.

8. Conclusion

In conclusion, carbon steel seamless tubes are essential for providing durable structural support in various applications. Their exceptional strength, corrosion resistance, cost-effectiveness, and lightweight design make them a superior choice for construction and engineering projects. Understanding their benefits and applications can help project managers, engineers, and architects make informed decisions about materials, ensuring the longevity and safety of structures. By incorporating carbon steel seamless tubes into modern construction, we can create a safer, more sustainable environment while reducing long-term costs and maintenance efforts.

Hot Tags: