Leading Smls Pipe and fittings supplier from China since 1991

Understanding Seamless Steel Pipe API 5L X60: Key Features and Applications

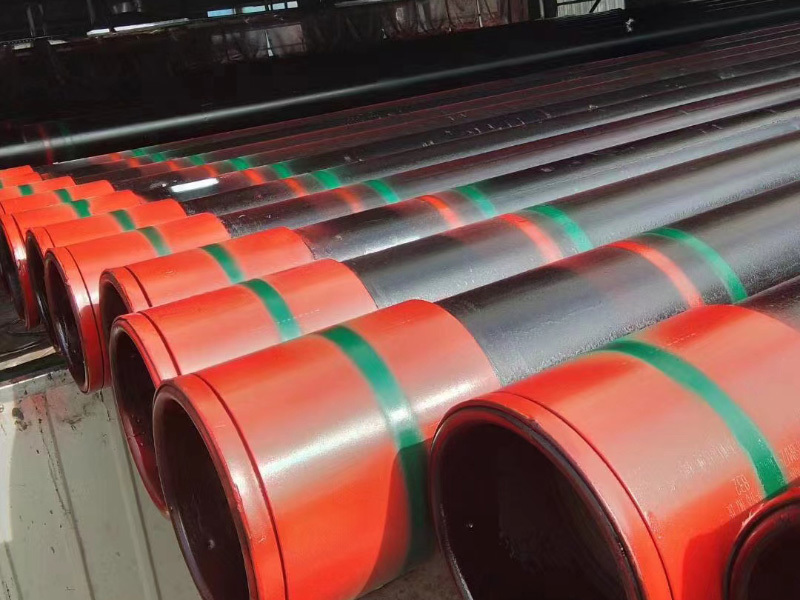

Seamless steel pipe API 5L X60 is a vital component in the construction and decoration materials industry, particularly within the realm of structural piping. Specified under the American Petroleum Institute (API) standards, API 5L X60 is designed to meet the rigorous demands of the oil and gas industry but is widely used in various construction applications due to its superior properties. One of

Nov 26,2025

Seamless steel pipe API 5L X60 is a vital component in the construction and decoration materials industry, particularly within the realm of structural piping. Specified under the American Petroleum Institute (API) standards, API 5L X60 is designed to meet the rigorous demands of the oil and gas industry but is widely used in various construction applications due to its superior properties.

One of the most significant features of seamless steel pipes is their manufacturing process. Unlike welded pipes, seamless pipes are created from a solid round steel billet, which is heated and then pierced to create a hollow tube. This process results in a product that has no welded seams, offering improved strength and resilience. For API 5L X60, this means enhanced performance under high pressure and high temperature, making it an ideal choice for transporting fluids, gases, and other materials in demanding environments.

When discussing seamless steel pipe API 5L X60, it is crucial to consider its chemical composition and mechanical properties. The "X60" designation indicates a minimum yield strength of 60,000 psi, which translates to exceptional durability and reliability. This grade, therefore, is often chosen for applications requiring robust materials that can withstand significant stress and harsh conditions.

In terms of applications, seamless steel pipe API 5L X60 is widely utilized in pipelines, particularly those carrying oil, natural gas, and water. Its high strength-to-weight ratio and excellent corrosion resistance ensure that these pipes can endure the rigors of environmental exposure and operational demands. Additionally, they are preferred in structural applications such as support beams and frames, where strength is paramount.

Another advantage of seamless steel pipe API 5L X60 is its versatility. It can be used in various industries beyond oil and gas, including construction, automotive, and manufacturing. This adaptability makes it a valuable asset for contractors and engineers who require reliable materials that can be employed in diverse applications.

Moreover, the seamless design of these pipes allows for easier installation and fewer complications during the construction process. Because they are produced in a continuous length, they minimize the need for joints and welds, leading to fewer potential points of failure. This characteristic not only enhances the structural integrity of the installation but also reduces maintenance and inspection requirements over time.

In summary, seamless steel pipe API 5L X60 stands out in the building and decoration materials sector for its strength, durability, and versatility. Its unique properties make it a preferred choice for a wide range of applications, ensuring that projects can proceed with confidence and reliability. Understanding these attributes is essential for professionals in the construction industry seeking high-quality piping solutions.

One of the most significant features of seamless steel pipes is their manufacturing process. Unlike welded pipes, seamless pipes are created from a solid round steel billet, which is heated and then pierced to create a hollow tube. This process results in a product that has no welded seams, offering improved strength and resilience. For API 5L X60, this means enhanced performance under high pressure and high temperature, making it an ideal choice for transporting fluids, gases, and other materials in demanding environments.

When discussing seamless steel pipe API 5L X60, it is crucial to consider its chemical composition and mechanical properties. The "X60" designation indicates a minimum yield strength of 60,000 psi, which translates to exceptional durability and reliability. This grade, therefore, is often chosen for applications requiring robust materials that can withstand significant stress and harsh conditions.

In terms of applications, seamless steel pipe API 5L X60 is widely utilized in pipelines, particularly those carrying oil, natural gas, and water. Its high strength-to-weight ratio and excellent corrosion resistance ensure that these pipes can endure the rigors of environmental exposure and operational demands. Additionally, they are preferred in structural applications such as support beams and frames, where strength is paramount.

Another advantage of seamless steel pipe API 5L X60 is its versatility. It can be used in various industries beyond oil and gas, including construction, automotive, and manufacturing. This adaptability makes it a valuable asset for contractors and engineers who require reliable materials that can be employed in diverse applications.

Moreover, the seamless design of these pipes allows for easier installation and fewer complications during the construction process. Because they are produced in a continuous length, they minimize the need for joints and welds, leading to fewer potential points of failure. This characteristic not only enhances the structural integrity of the installation but also reduces maintenance and inspection requirements over time.

In summary, seamless steel pipe API 5L X60 stands out in the building and decoration materials sector for its strength, durability, and versatility. Its unique properties make it a preferred choice for a wide range of applications, ensuring that projects can proceed with confidence and reliability. Understanding these attributes is essential for professionals in the construction industry seeking high-quality piping solutions.

Hot Tags: