Leading Smls Pipe and fittings supplier from China since 1991

Steel Casing Pipe: A Key Player in Electrical Safety Regulations

Steel Casing Pipe: A Key Player in Electrical Safety Regulations Table of Contents 1. Introduction to Steel Casing Pipes 2. Importance of Electrical Safety Regulations 2.1 Understanding Electrical Hazards 2.2 The Role of Safety Regulations in the Electrical Industry 3. What is a Steel Casing Pipe? 4. Specifications and Standards for Steel Casing Pipes 4.1 Material Composition 4.2 Dimensions and Th

Jun 27,2025

Steel Casing Pipe: A Key Player in Electrical Safety Regulations

Table of Contents

1. Introduction to Steel Casing Pipes

2. Importance of Electrical Safety Regulations

2.1 Understanding Electrical Hazards

2.2 The Role of Safety Regulations in the Electrical Industry

3. What is a Steel Casing Pipe?

4. Specifications and Standards for Steel Casing Pipes

4.1 Material Composition

4.2 Dimensions and Thickness

4.3 Coating and Corrosion Resistance

5. Benefits of Using Steel Casing Pipes in Electrical Applications

5.1 Enhanced Safety Protocols

5.2 Durability and Longevity

5.3 Versatility in Applications

6. Installation Guidelines for Steel Casing Pipes

7. Compliance with Electrical Safety Standards

7.1 National Electrical Code (NEC) Requirements

7.2 International Electrotechnical Commission (IEC) Standards

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Steel Casing Pipes

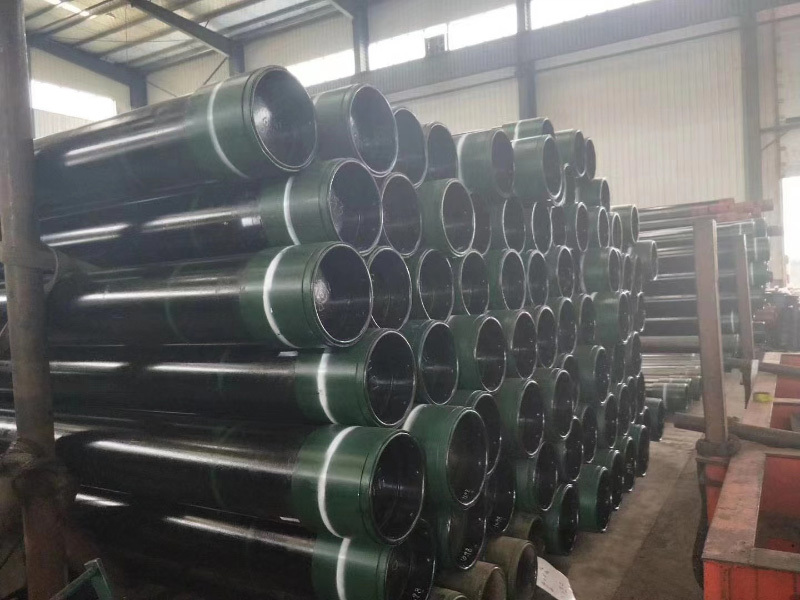

Steel casing pipes are vital components in various electrical installations, providing protection and support for electrical cables and conduits. Their robust structure and resistance to environmental factors make them an ideal choice for ensuring electrical safety in numerous applications. This article explores the significance of steel casing pipes, their specifications, benefits, and compliance with safety regulations.

2. Importance of Electrical Safety Regulations

2.1 Understanding Electrical Hazards

Electricity presents inherent hazards, including shock, electrocution, and fire risks. Understanding these dangers is essential for any professional working in the electrical industry. Implementing safety regulations helps mitigate these risks, ensuring the protection of both workers and the public.

2.2 The Role of Safety Regulations in the Electrical Industry

Safety regulations are designed to establish guidelines and protocols that promote safe practices in electrical installations. Compliance with these regulations helps prevent accidents and ensures that electrical systems operate efficiently and safely.

3. What is a Steel Casing Pipe?

A steel casing pipe is a tubular structure made from high-quality steel, predominantly used to encase electrical conduits and cables. It provides a protective barrier against mechanical damage, moisture, and environmental factors that can compromise electrical safety. Steel casing pipes are commonly used in underground installations, where they serve as a protective conduit for cables in harsh conditions.

4. Specifications and Standards for Steel Casing Pipes

4.1 Material Composition

Steel casing pipes are primarily composed of carbon steel, known for its strength and durability. The material is often treated to enhance its corrosion resistance, ensuring a longer lifespan even in adverse conditions.

4.2 Dimensions and Thickness

The dimensions of steel casing pipes vary depending on the application. They are available in different diameters and wall thicknesses, allowing for versatility in installation. It’s essential to choose the appropriate size to accommodate the specific electrical cables being used.

4.3 Coating and Corrosion Resistance

Many steel casing pipes come with protective coatings, such as galvanized or polyurethane, to prevent rust and corrosion. These coatings are crucial in extending the life of the pipes, especially in environments where moisture is prevalent.

5. Benefits of Using Steel Casing Pipes in Electrical Applications

5.1 Enhanced Safety Protocols

Using steel casing pipes significantly enhances safety protocols in electrical installations. They provide a robust barrier that protects electrical cables from damage, reducing the risk of electrical failures and accidents.

5.2 Durability and Longevity

Steel casing pipes are known for their durability and longevity. Unlike plastic alternatives, steel is resistant to extreme temperatures, UV radiation, and physical impacts, making it suitable for various environmental conditions.

5.3 Versatility in Applications

Steel casing pipes can be utilized in numerous applications, including telecommunications, power distribution, and other electrical works. Their versatility makes them a preferred choice for contractors and engineers.

6. Installation Guidelines for Steel Casing Pipes

Proper installation is crucial to ensuring the effectiveness of steel casing pipes in electrical applications. Here are some key guidelines:

- **Site Assessment:** Conduct a thorough site assessment to determine the appropriate location and depth for installation.

- **Trenching:** Dig trenches that comply with local regulations. The depth and width of the trench should accommodate the steel casing pipe and any surrounding materials.

- **Pipe Placement:** Carefully place the steel casing pipe in the trench, ensuring it is level and properly aligned.

- **Backfilling:** Use appropriate backfill material to support the pipe, reducing the risk of damage from soil movement.

7. Compliance with Electrical Safety Standards

7.1 National Electrical Code (NEC) Requirements

The NEC outlines specific requirements for the installation and use of steel casing pipes in electrical systems. Compliance with these regulations is mandatory to ensure safety and reliability in electrical installations.

7.2 International Electrotechnical Commission (IEC) Standards

The IEC sets international standards for electrical safety, including guidelines for the use of materials like steel casing pipes. Adhering to these standards helps maintain global safety benchmarks in electrical work.

8. Frequently Asked Questions (FAQs)

1. What is the primary purpose of steel casing pipes in electrical installations?

Steel casing pipes primarily protect electrical cables and conduits from mechanical damage and environmental factors.

2. Are steel casing pipes suitable for underground installations?

Yes, steel casing pipes are ideal for underground installations due to their durability and resistance to environmental stressors.

3. How do I determine the correct size of a steel casing pipe for my project?

The correct size depends on the dimensions of the electrical cables being used and the installation requirements. Consult with a professional if needed.

4. What maintenance is required for steel casing pipes?

Regular inspections for rust or damage are essential. Additionally, ensure that any protective coatings remain intact.

5. Can plastic casing pipes be used as an alternative to steel casing pipes?

While plastic casing pipes offer some benefits, steel casing pipes provide superior strength and durability, making them a better choice for many applications.

9. Conclusion

Steel casing pipes play a critical role in electrical safety regulations, providing necessary protection for electrical cables and conduits. Their robust construction, compliance with safety standards, and versatility make them an essential component in various electrical installations. By following proper installation guidelines and understanding the benefits of steel casing pipes, electrical professionals can significantly enhance safety and reliability in their projects. Embracing these practices not only protects infrastructure but also contributes to the overall safety of electrical systems.

Hot Tags:

PREVIOUS: