Leading Smls Pipe and fittings supplier from China since 1991

Exploring the Benefits of Steel Casing in Electrical Insulation

Exploring the Benefits of Steel Casing in Electrical Insulation Table of Contents 1. Introduction to Electrical Insulation 2. What is Steel Casing? 3. Advantages of Steel Casing in Electrical Insulation 3.1 Durability and Longevity 3.2 Safety Standards and Compliance 3.3 Cost-Effectiveness 3.4 Resistance to Environmental Factors

Jul 09,2025

Exploring the Benefits of Steel Casing in Electrical Insulation

Table of Contents

- 1. Introduction to Electrical Insulation

- 2. What is Steel Casing?

- 3. Advantages of Steel Casing in Electrical Insulation

- 3.1 Durability and Longevity

- 3.2 Safety Standards and Compliance

- 3.3 Cost-Effectiveness

- 3.4 Resistance to Environmental Factors

- 4. Applications of Steel Casing in Electrical Installations

- 5. Choosing the Right Steel Casing

- 6. Installation Best Practices for Steel Casing

- 7. Frequently Asked Questions (FAQs)

- 8. Conclusion

1. Introduction to Electrical Insulation

Electrical insulation is a critical component in electrical engineering, ensuring the safe and efficient transmission of electricity. Proper insulation protects users from electrical shocks and prevents short circuits, which can lead to catastrophic failures. As technology advances, the materials and methodologies used in insulation must evolve to enhance safety and performance. Steel casing has emerged as a robust solution, providing numerous benefits for electrical insulation applications.

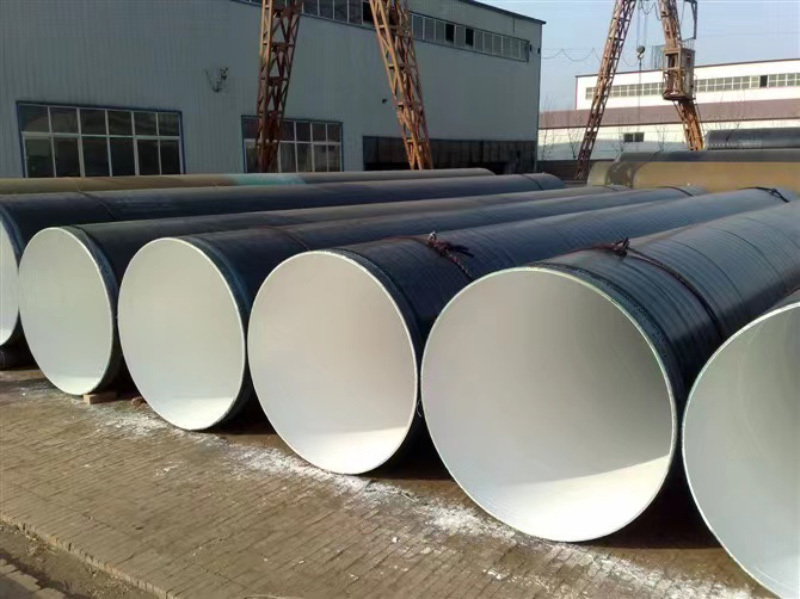

2. What is Steel Casing?

Steel casing refers to a protective layer made from steel that encases electrical wiring and components. This casing serves multiple purposes, including shielding against physical damage, providing electrical insulation, and enhancing overall safety in electrical systems. Steel casing can be manufactured in various sizes and strengths to accommodate different applications, making it a versatile choice for many industries.

3. Advantages of Steel Casing in Electrical Insulation

Steel casing is gaining popularity in electrical insulation applications due to its numerous advantages. Below, we delve into the key benefits that make steel casing an ideal choice for electrical insulation.

3.1 Durability and Longevity

One of the standout features of steel casing is its exceptional durability. Unlike traditional insulating materials, steel can withstand physical impacts, extreme temperatures, and various environmental conditions. This durability ensures that electrical installations remain operational for extended periods without the need for frequent replacements or repairs. In critical settings, such as industrial or outdoor environments, the longevity of steel casing significantly reduces maintenance costs over time.

3.2 Safety Standards and Compliance

Safety is paramount in electrical installations. Steel casing meets stringent safety standards and compliance regulations, providing peace of mind to users and installers alike. It minimizes the risk of electrical shocks by offering a robust barrier between live wires and external surfaces. Additionally, the high resistance of steel to fire and corrosion further enhances safety, making it a preferred choice for high-risk environments.

3.3 Cost-Effectiveness

While the initial investment in steel casing may be higher than alternatives, the long-term cost-effectiveness is undeniable. The durability and longevity of steel significantly reduce replacement and maintenance expenses. Furthermore, less frequent repairs contribute to overall savings, making steel casing a financially sound choice for both small and large-scale electrical projects.

3.4 Resistance to Environmental Factors

Electrical installations often face challenging environmental conditions, including moisture, chemicals, and temperature fluctuations. Steel casing offers superior resistance to these factors, ensuring that the insulation remains effective over time. This resilience protects electrical systems from degradation, enhancing their reliability and performance in various settings.

4. Applications of Steel Casing in Electrical Installations

Steel casing is widely used across numerous industries due to its versatility and benefits. Some common applications include:

- **Industrial Electrical Systems**: In factories and manufacturing plants, steel casing protects wiring from mechanical damage, ensuring reliable operations.

- **Outdoor Installations**: Steel casing is ideal for outdoor electrical systems, providing resistance against the elements, including rain, snow, and UV radiation.

- **Infrastructure Projects**: In infrastructure projects such as bridges and tunnels, steel casing ensures that electrical systems remain safe and operational despite environmental stresses.

- **Commercial Buildings**: Steel casing is frequently used within commercial buildings to safeguard electrical wiring and enhance overall safety.

5. Choosing the Right Steel Casing

Selecting the appropriate steel casing for electrical insulation requires careful consideration of several factors:

- **Material Grade**: Different grades of steel offer varying levels of strength and corrosion resistance. Assess the specific requirements of your project to determine the best material.

- **Diameter and Thickness**: The size of the casing should align with the electrical components it will protect. Ensure that the diameter and thickness are suitable for your specific application.

- **Environmental Conditions**: Consider the environmental factors the casing will be exposed to, such as humidity, temperature ranges, and potential chemical exposure.

- **Compliance Standards**: Ensure that the selected casing meets local and industry-specific safety standards.

6. Installation Best Practices for Steel Casing

Proper installation is crucial to maximizing the benefits of steel casing in electrical insulation. Here are some best practices to follow:

- **Professional Installation**: Engage qualified electricians who are familiar with steel casing installations to ensure compliance with all safety standards and regulations.

- **Secure Connections**: Ensure that all connections are secure and properly sealed to prevent moisture ingress, which could compromise insulation quality.

- **Regular Inspections**: Conduct routine inspections to check for signs of wear, corrosion, or damage. Early detection can mitigate potential issues and ensure the longevity of the installation.

- **Adhere to Manufacturer Guidelines**: Always follow the manufacturer’s guidelines for installation and maintenance to maximize the efficacy of the steel casing.

7. Frequently Asked Questions (FAQs)

What is the primary benefit of using steel casing in electrical insulation?

The primary benefit of using steel casing is its exceptional durability and ability to provide a robust barrier against physical damage and environmental factors, ensuring the reliability and safety of electrical installations.

How does steel casing enhance safety in electrical systems?

Steel casing enhances safety by minimizing the risk of electrical shocks and protecting wiring from damage. Its resistance to fire and corrosion further increases safety in high-risk environments.

Is steel casing suitable for outdoor electrical installations?

Yes, steel casing is ideal for outdoor installations due to its resistance to moisture, UV radiation, and extreme weather conditions.

What factors should be considered when choosing steel casing?

When choosing steel casing, consider material grade, diameter and thickness, environmental conditions, and compliance standards.

How can installation practices affect the performance of steel casing?

Proper installation practices, including secure connections and adherence to manufacturer guidelines, significantly impact the performance and longevity of steel casing in electrical applications.

8. Conclusion

Steel casing serves as a vital component in electrical insulation, offering unparalleled durability, safety, and cost-effectiveness. Its ability to withstand harsh conditions while ensuring compliance with safety standards makes it a preferred choice for a variety of applications. By understanding the benefits and best practices associated with steel casing, electrical engineers and contractors can enhance the safety and reliability of their installations. Investing in steel casing is not just a smart choice; it’s a commitment to excellence in electrical engineering.

Hot Tags: