Leading Smls Pipe and fittings supplier from China since 1991

Exploring the Benefits of Seamless Steel Tubes in Construction: A Comprehensive Guide

Exploring the Benefits of Seamless Steel Tubes in Construction Table of Contents 1. Introduction 2. What Are Seamless Steel Tubes? 3. Manufacturing Process of Seamless Steel Tubes 4. Advantages of Seamless Steel Tubes in Construction 5. Applications of Seamless Steel Tubes in Construction 6. Seamless vs. Welded Steel Tubes: A Comparative Analysis 7. Sustainability and

Sep 01,2025

Exploring the Benefits of Seamless Steel Tubes in Construction

Table of Contents

- 1. Introduction

- 2. What Are Seamless Steel Tubes?

- 3. Manufacturing Process of Seamless Steel Tubes

- 4. Advantages of Seamless Steel Tubes in Construction

- 5. Applications of Seamless Steel Tubes in Construction

- 6. Seamless vs. Welded Steel Tubes: A Comparative Analysis

- 7. Sustainability and Environmental Impact

- 8. Case Studies: Real-World Applications of Seamless Steel Tubes

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction

In the realm of construction, material selection is crucial for the integrity, durability, and overall success of a project. **Seamless steel tubes** stand out as one of the most advantageous options available today. Their unique properties make them suitable for a wide variety of applications, from structural support to fluid transport. In this article, we will explore the benefits of using seamless steel tubes, shedding light on why they are becoming increasingly popular in the construction industry.

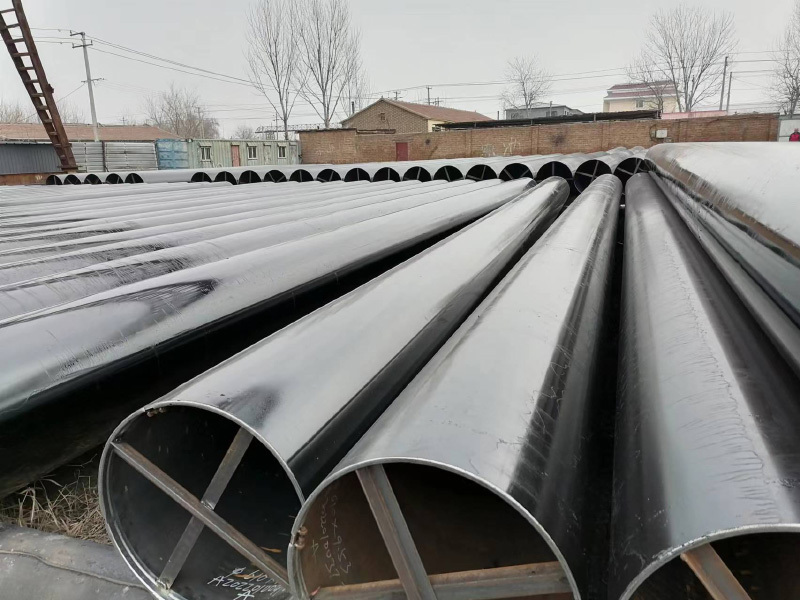

2. What Are Seamless Steel Tubes?

Seamless steel tubes are hollow sections of steel that are manufactured without any seams or welds. Unlike welded tubes, seamless tubes are produced from a solid round steel billet, which is heated and then stretched to form a tube. This manufacturing technique results in a tube that is inherently stronger and more reliable than its welded counterparts. The absence of seams minimizes the risk of failure under pressure or stress, making seamless steel tubes essential in high-pressure applications.

3. Manufacturing Process of Seamless Steel Tubes

The manufacturing process of seamless steel tubes involves several key steps:

3.1. Billet Preparation

The journey begins with the selection of high-quality steel billets, which are cut to the appropriate length.

3.2. Heating

The billets are heated in a furnace to a temperature that makes them malleable, typically around 2,300°F (1,260°C).

3.3. Piercing

Once heated, the billets are pierced to create a hollow center. This step is crucial in transforming the solid billet into a tube shape.

3.4. Elongation

The pierced billets are then elongated using a process called rotary piercing, which further forms the tube while maintaining its seamless integrity.

3.5. Further Processing

After elongation, the tubes undergo additional processing like heat treatment, sizing, and finishing to meet specific dimensional and strength requirements.

4. Advantages of Seamless Steel Tubes in Construction

Seamless steel tubes offer numerous benefits that make them an ideal choice for construction projects.

4.1. Enhanced Strength and Durability

Due to their seamless construction, these tubes exhibit higher strength and resistance to stress. This makes them suitable for critical applications where safety and reliability are paramount.

4.2. Higher Pressure Ratings

Seamless tubes can withstand higher internal pressures compared to welded tubes. This characteristic is essential for applications in oil and gas pipelines, as well as water transportation systems.

4.3. Better Corrosion Resistance

Seamless steel tubes can be treated with various coatings to enhance their corrosion resistance, making them suitable for outdoor and marine environments.

4.4. Cost-Effectiveness

While the initial cost of seamless tubes may be higher, their long-term durability and reduced maintenance needs can lead to significant savings over time.

4.5. Versatility

Seamless steel tubes come in various sizes and grades, allowing for flexibility in design and application across multiple construction projects.

5. Applications of Seamless Steel Tubes in Construction

The use of seamless steel tubes spans a wide range of applications:

5.1. Structural Supports

Seamless tubes are commonly used in constructing beams, columns, and other structural elements due to their strength and ability to bear heavy loads.

5.2. Piping Systems

In plumbing and HVAC systems, seamless tubes are favored for their high-pressure ratings and resistance to corrosion.

5.3. Oil and Gas Industry

Seamless steel tubes are essential in pipelines and drilling applications, where they withstand extreme conditions.

5.4. Automotive Applications

Manufacturers utilize seamless tubes for exhaust systems and chassis components, benefiting from their durability and lightweight properties.

5.5. Specialty Applications

From aerospace to medical devices, seamless steel tubes find uses in niche markets where reliability is non-negotiable.

6. Seamless vs. Welded Steel Tubes: A Comparative Analysis

Understanding the differences between seamless and welded steel tubes is vital for informed decision-making.

6.1. Construction and Strength

Seamless tubes exhibit superior strength due to their lack of seams, which are potential weak points in welded tubes.

6.2. Manufacturing Process

The manufacturing of seamless tubes is more complex and time-consuming, often leading to higher costs. However, these costs are often offset by their long-term performance.

6.3. Usage Scenarios

While welded tubes can be suitable for low-pressure applications, seamless tubes are preferred for critical applications requiring high pressure and safety.

7. Sustainability and Environmental Impact

In today's environmentally-conscious world, sustainability in construction materials is more important than ever.

7.1. Recyclability

Seamless steel tubes are fully recyclable, contributing to a circular economy and reducing waste in construction.

7.2. Resource Efficiency

The manufacturing process of seamless tubes, while resource-intensive, can lead to longer-lasting products that reduce the need for frequent replacements.

7.3. Innovation in Materials

Advances in material science are leading to the development of sustainable steel grades that offer enhanced properties while being less harmful to the environment.

8. Case Studies: Real-World Applications of Seamless Steel Tubes

To illustrate the practical benefits of seamless steel tubes, we present several case studies:

8.1. The Burj Khalifa

The structural supports of the Burj Khalifa utilize seamless steel tubes, showcasing their ability to withstand extreme heights and loads.

8.2. Offshore Oil Platforms

Seamless tubes are integral to the construction of offshore oil platforms, where they are exposed to harsh marine environments.

8.3. High-Speed Rail Projects

Seamless steel tubes are used in the construction of high-speed rail systems, providing lightweight and durable components that enhance performance.

9. Frequently Asked Questions

9.1. What are seamless steel tubes made of?

Seamless steel tubes are primarily made from carbon steel, alloy steel, or stainless steel, depending on the application requirements.

9.2. How are seamless steel tubes different from welded tubes?

Seamless tubes are manufactured without seams, resulting in greater strength and higher pressure ratings when compared to welded tubes.

9.3. What industries use seamless steel tubes?

Seamless steel tubes are used across a variety of industries, including construction, automotive, oil and gas, and aerospace.

9.4. Are seamless steel tubes more expensive than welded tubes?

Although seamless tubes typically have a higher upfront cost, their durability and long lifespan can lead to cost savings over time.

9.5. Can seamless steel tubes be recycled?

Yes, seamless steel tubes are fully recyclable, contributing to a more sustainable construction process.

10. Conclusion

Seamless steel tubes offer numerous benefits that make them an invaluable asset in modern construction. Their unmatched strength, durability, and versatility position them as the material of choice for a wide range of applications. As the construction industry continues to evolve, embracing innovative materials like seamless steel tubes not only enhances project outcomes but also contributes to sustainable building practices. By understanding the advantages and applications of seamless steel tubes, contractors and builders can make informed decisions that ensure the success and longevity of their projects.

Hot Tags:

PREVIOUS: