Leading Smls Pipe and fittings supplier from China since 1991

The Advantages of Using Carbon Steel Seamless Tubes in Construction Projects

The Advantages of Using Carbon Steel Seamless Tubes in Construction Projects Table of Contents Introduction to Carbon Steel Seamless Tubes Unmatched Structural Integrity of Carbon Steel Seamless Tubes Corrosion Resistance: A Key Benefit Cost-Effectiveness of Carbon Steel Seamless Tubes Sustainability of Carbon Steel in Construction Versatility in Applications Installat

Sep 29,2025

The Advantages of Using Carbon Steel Seamless Tubes in Construction Projects

Table of Contents

- Introduction to Carbon Steel Seamless Tubes

- Unmatched Structural Integrity of Carbon Steel Seamless Tubes

- Corrosion Resistance: A Key Benefit

- Cost-Effectiveness of Carbon Steel Seamless Tubes

- Sustainability of Carbon Steel in Construction

- Versatility in Applications

- Installation and Maintenance Considerations

- Future Trends in Carbon Steel Seamless Tube Usage

- Conclusion

- Frequently Asked Questions (FAQs)

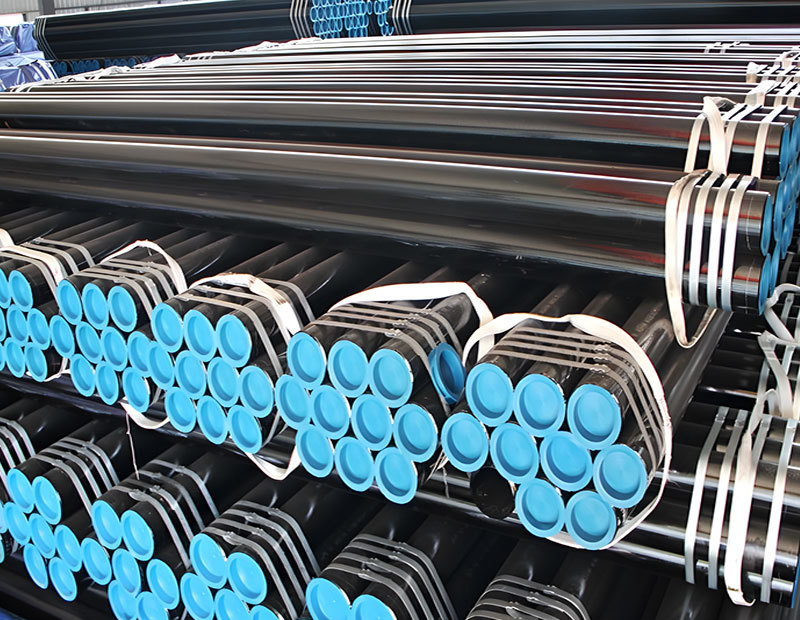

Introduction to Carbon Steel Seamless Tubes

In the ever-evolving world of construction materials, **carbon steel seamless tubes** have emerged as a superior choice for various applications. Their smooth, continuous structure allows for higher pressure tolerance and provides an essential solution for architects and engineers looking to enhance the durability and safety of their projects. Understanding the numerous benefits of these tubes can significantly impact the decision-making process in construction.

Unmatched Structural Integrity of Carbon Steel Seamless Tubes

One of the primary reasons for choosing carbon steel seamless tubes is their **exceptional structural integrity**. Unlike welded tubes, seamless tubes are formed from a single piece of metal, eliminating any weak points that may arise from welding. This feature provides:

Enhanced Load-Bearing Capacity

Carbon steel seamless tubes exhibit impressive load-bearing capacities, making them ideal for construction projects that require robust structural support. Their ability to withstand high levels of stress and pressure ensures the safety and reliability of various applications, from scaffolding to piping systems.

Improved Safety Standards

The integrity of seamless tubes directly translates to enhanced safety in construction. With fewer potential failure points, the risk of structural failure is minimized, making these tubes a preferred choice for critical applications where safety is paramount.

Corrosion Resistance: A Key Benefit

In construction, **exposure to environmental elements** can lead to material degradation over time. Carbon steel seamless tubes are often treated or coated to enhance their resistance to corrosion. This treatment provides the following advantages:

Longevity of Materials

By choosing carbon steel seamless tubes, you ensure that your structures will last longer, reducing the need for frequent replacements. Their resistance to rust and corrosion ensures that the integrity of the materials remains intact for years, thereby saving costs in the long run.

Maintenance Reduction

The inherent properties of carbon steel seamless tubes also lead to lower maintenance requirements. This aspect can significantly reduce operational costs for construction projects, as less frequent inspections and repairs are needed.

Cost-Effectiveness of Carbon Steel Seamless Tubes

When evaluating construction materials, cost is a critical factor. Carbon steel seamless tubes offer several financial benefits:

Affordable Material Costs

Compared to other materials such as stainless steel, carbon steel is relatively inexpensive. Its cost-effectiveness makes it an attractive option for large-scale construction projects, allowing for budget flexibility while maintaining high-quality standards.

Reduced Lifecycle Costs

While the initial investment in carbon steel seamless tubes may be competitive, their durability and low maintenance requirements contribute to significantly reduced lifecycle costs. This long-term savings potential makes them an intelligent choice for builders and project managers.

Sustainability of Carbon Steel in Construction

In today's environmentally conscious world, choosing sustainable materials is more important than ever. Carbon steel seamless tubes meet this demand through:

Recyclability

Carbon steel is highly recyclable. When a construction project reaches its end-of-life, the components made from carbon steel can be repurposed into new products, reducing waste and environmental impact. This feature aligns with modern construction practices that prioritize sustainability.

Lower Carbon Footprint

The production of carbon steel seamless tubes generally requires less energy compared to alternative materials. By opting for these tubes, construction projects can contribute to a lower overall carbon footprint, aligning with global sustainability goals.

Versatility in Applications

The versatility of carbon steel seamless tubes makes them suitable for a wide range of applications, including:

Structural Applications

These tubes are used in various structural applications, such as beams, columns, and frames. Their strength and durability make them a go-to choice for load-bearing structures.

Piping Systems

In industrial and commercial settings, seamless tubes are widely used for piping systems that transport liquids and gases. Their ability to withstand high pressures and temperatures makes them ideal for demanding environments.

Automotive and Machinery Components

Carbon steel seamless tubes are not limited to construction. They are also utilized in the manufacturing of automotive and machinery components, where strength and reliability are critical.

Installation and Maintenance Considerations

While the benefits of carbon steel seamless tubes are numerous, proper installation and maintenance practices are crucial for maximizing their potential:

Expert Installation

Engaging skilled professionals for the installation of carbon steel seamless tubes ensures that they are fitted correctly. Improper installation can compromise the structural integrity and performance of the tubes.

Routine Inspections

Even with their low maintenance needs, routine inspections can help identify any potential issues before they escalate. Regular checks can improve the longevity and performance of the seamless tubes.

Future Trends in Carbon Steel Seamless Tube Usage

As construction technology advances, the role of carbon steel seamless tubes is expected to evolve further. Key trends to watch for include:

Innovative Coatings

The development of advanced coatings to enhance corrosion resistance and durability is on the rise. These innovations promise to increase the lifespan and performance of carbon steel seamless tubes.

Smart Construction Integration

The integration of smart technologies into construction materials is gaining traction. Future carbon steel seamless tubes may feature sensors that monitor structural integrity in real-time, providing valuable data for maintenance and safety.

Conclusion

Choosing carbon steel seamless tubes for construction projects offers numerous benefits, including unmatched structural integrity, cost-effectiveness, and sustainability. Their versatility makes them suitable for various applications, contributing to safer, more reliable structures. As the construction industry continues to evolve, carbon steel seamless tubes will undoubtedly remain at the forefront, offering solutions that meet the demands of modern construction.

Frequently Asked Questions (FAQs)

1. What are carbon steel seamless tubes?

Carbon steel seamless tubes are hollow tubes made from carbon steel that do not have any weld seams. They are manufactured through a process that ensures a continuous structure, offering superior strength and durability.

2. How do carbon steel seamless tubes compare to welded tubes?

Carbon steel seamless tubes provide greater structural integrity, as they lack weld seams that can weaken the material. This results in higher load-bearing capacities and reduced risk of failure.

3. Are carbon steel seamless tubes environmentally friendly?

Yes, carbon steel is highly recyclable, and its production generally requires less energy compared to other materials. Choosing carbon steel seamless tubes can contribute to a lower carbon footprint.

4. What applications are best suited for carbon steel seamless tubes?

These tubes are versatile and can be used in structural applications, piping systems, and manufacturing automotive and machinery components, among others.

5. How can I ensure proper installation and maintenance of carbon steel seamless tubes?

Engaging skilled professionals for installation and conducting routine inspections can help ensure that carbon steel seamless tubes perform optimally and maintain their structural integrity over time.

Hot Tags:

PREVIOUS: